Inkqubo yokuveliswa kweMargarine

Inkqubo yokuveliswa kweMargarine

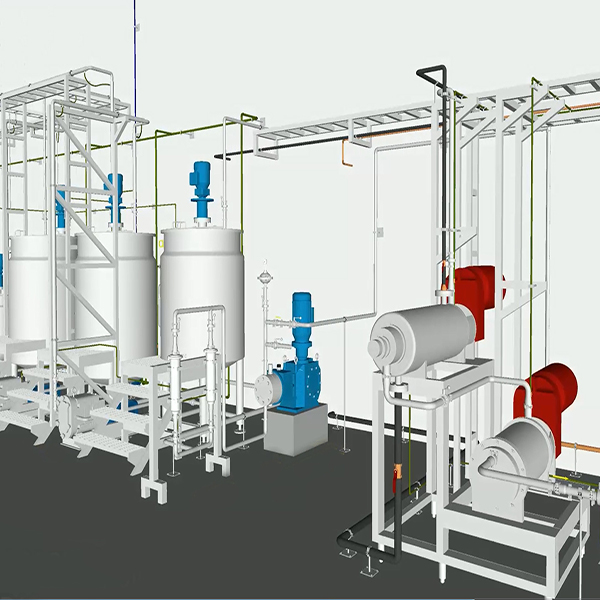

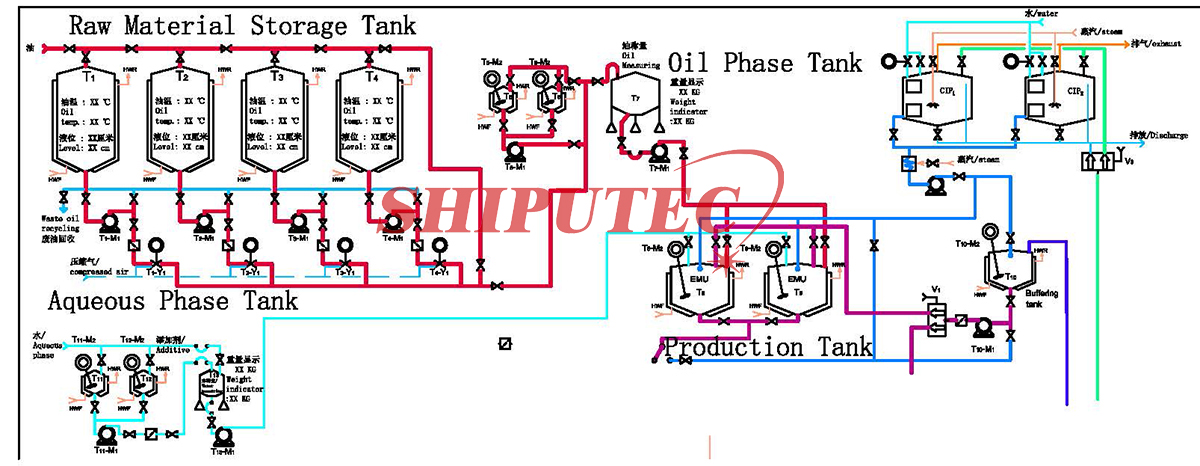

Ukuveliswa kwemargarine kubandakanya iinxalenye ezimbini: ukulungiswa kwezinto eziluhlaza kunye nokupholisa kunye neplastiki. Izixhobo eziphambili ziquka iitanki zokulungiselela, ipompo ye-HP, i-votator (i-scraped surface heat exchanger), umatshini we-pin rotor, iyunithi yefriji, umatshini wokuzalisa imajarini kunye njl.

Inkqubo yangaphambili ngumxube wesigaba seoli kunye nesigaba samanzi, umlinganiselo kunye ne-emulsification yomxube wesigaba seoli kunye nesigaba samanzi, ukwenzela ukuba kulungiswe ukutya okubonakalayo kwenkqubo yokugqibela. Inkqubo yokugqibela kukupholisa ngokuqhubekayo iplastiki kunye nokupakishwa kwemveliso.

Inkqubo yokulungiselela izinto ezikrwada zemajarini iboniswe kuMfanekiso 1:

- 1.Ubisi oluvundisiweyo

Ezinye ifomula imajarini ukongeza ubisi, kunye nobisi emva lactic acid iintsholongwane ukuvubela unokuvelisa incasa efanayo cream yendalo, ngoko ke umzi-mveliso ukuya ubisi oluvundisiweyo kunye namanzi exutywe.

- 2.Ukuxuba amanzi

Izongezo zamanzi kunye ne-soluble water-soluble kwi-formula ye-margarine, njengobisi oluvundisiweyo, ityuwa, i-preservatives, njl., zongezwa kwisigaba samanzi sokuxuba kunye ne-tank yokulinganisa kwimilinganiselo emiselweyo yokugubha kunye nokuxuba, ukwenzela ukuba isigaba samanzi. amacandelo anyibilikiswa kwisisombululo esifanayo.

- 3.Ukuxuba isigaba se-oyile

Ioli ekrwada yeenkcazo ezahlukeneyo ixutywa kuqala kwitanki yokuxuba ioli ngokwemilinganiselo emiselweyo, emva koko izongezo ezinyibilikayo zeoli, ezifana ne-emulsifier, i-antioxidant, i-pigment e-soluble oil, i-oil-soluble cellulose, njl. isigaba se-oyile ngokomlinganiselo, sixutywe netanki yokulinganisa, kwaye sixutywe ukwenza isigaba se-oyile esifanayo.

- 4.I-emulsion

Injongo ye-emulsification ye-margarine kukwenza isigaba samanzi ngokulinganayo kwaye sihlakazeke ngokuzinzileyo kwisigaba seoli, kwaye i-dispersion degree ye-aqueous phase inempembelelo enkulu kumgangatho wemveliso. Ngenxa yokuba i-flavour ye-margarine ihambelana ngokusondeleyo nobukhulu bamaqhekeza esigaba samanzi, ukusasazwa kwe-microorganisms kuqhutyelwa kwinqanaba lamanzi, ubukhulu bebhaktheriya ngokubanzi yi-1-5 microns, ngoko ke amaconsi amanzi kwi-10-20. i-microns okanye uluhlu oluncinci lunokunciphisa ukusasazeka kwebhaktheriya, ngoko ke ukusabalalisa kwesigaba samanzi kukuhle kakhulu, iinqununu zesigaba samanzi zincinci kakhulu ziya kwenza i-margarine ilahlekelwe yincasa; Ukusabalalisa akwanelanga, i-particle yesigaba samanzi inkulu kakhulu, iya kwenza i-margarine yonakalise i-metamorphism. Ubudlelwane phakathi kweqondo lokusasazeka kwesigaba samanzi kwimajarini kunye nobume bemveliso bumalunga noku kulandelayo:

| 水滴直径 Ubungakanani bokwehla kwamanzi (微米 micrometer) | 人造奶油性质 (Taste of margarine) |

| ngaphantsi kwe-1 (malunga ne-80-85% yesigaba samanzi) | Incasa enzima kwaye encinci |

| 30-40 (ngaphantsi kwe-1% yesigaba samanzi) | Incasa elungileyo, kulula ukubola |

| I-1-5 (malunga ne-95% yesigaba samanzi) | Ukunambitheka okulungileyo, akukho lula ukubola |

| 5-10 (malunga ne-4% yesigaba samanzi) | |

| I-10-20 (malunga ne-1% yesigaba samanzi) |

Kungabonwa ukuba umsebenzi wokwenziwa kwe-emulsification kufuneka ufikelele kwinqanaba elithile leemfuno zokusasazwa.

Injongo yokuxuba isigaba samanzi kunye nesigaba seoli ngokwahlukileyo kwaye ngokulinganayo kunye nesigaba sangaphambili kukuqinisekisa ukuhambelana okufanayo kwe-emulsion yonke emva kwe-emulsification kunye nokuxuba ioli kunye namanzi izigaba ezimbini. Ukuxuba i-Emulsification kukuba, ingxaki yokusebenza i-50-60 degrees, isigaba samanzi songezwa kwisigaba seoli esilinganisiweyo, kwi-mechanical stirring okanye i-pump cycle cycle yokuvuselela, sisigaba samanzi esichithwa ngokupheleleyo kwisigaba seoli, ukubunjwa kwe-latex. Kodwa olu hlobo lwe-latex lwelwelo aluzinzanga kakhulu, ukuyeka ukuvuselela kunokuba kwi-oyile yebala lokudlala kunye nokwahlukana kwamanzi.

Emva kokuba i-emulsion edibeneyo ihanjiswe, inkqubo yokupholisa kunye neplastiki iqhutywe de kube imveliso ifakwe.

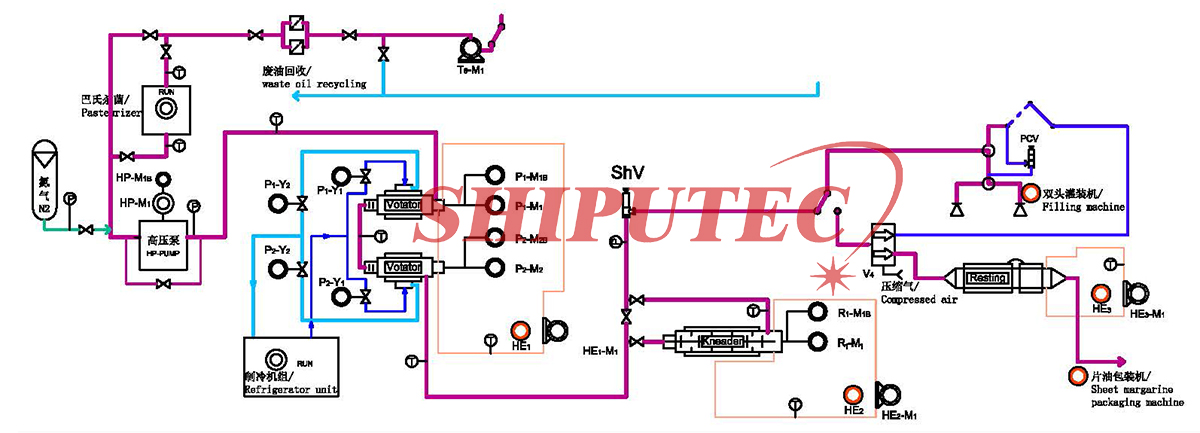

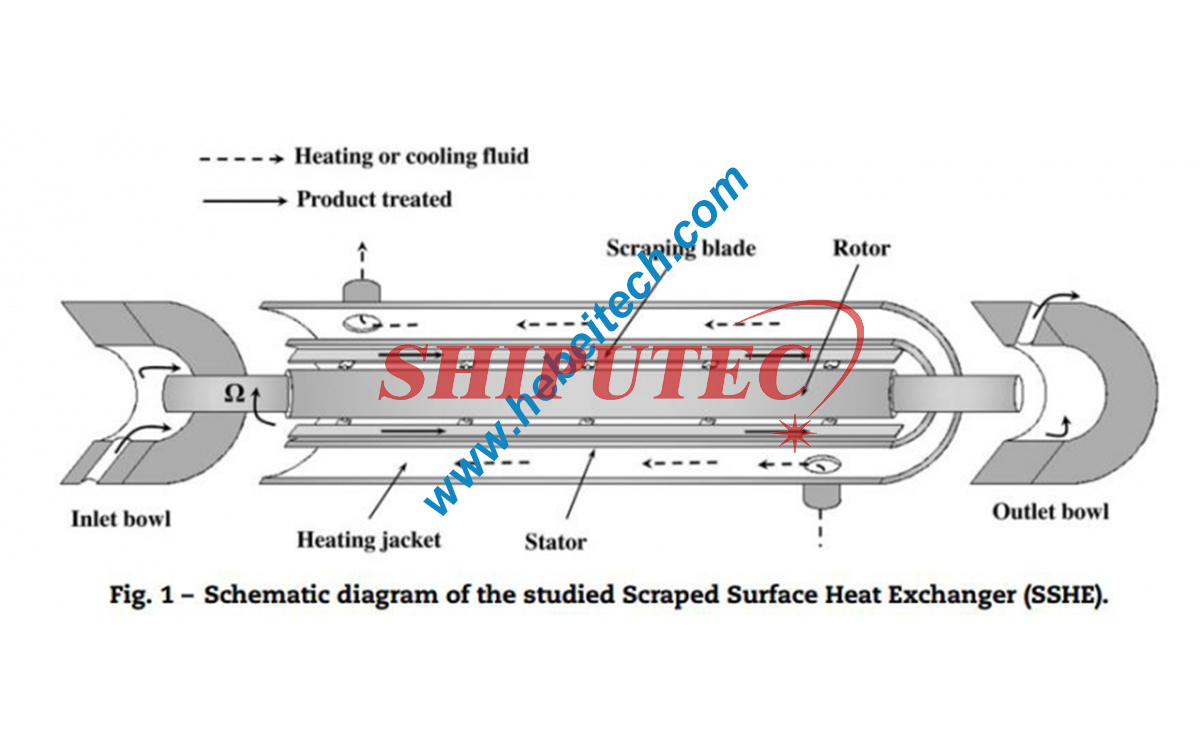

I-emulsion kufuneka ipholile kwaye ifakwe iplastiki ukuvelisa imveliso yemargarine eguquguqukayo. Okwangoku, ithatha ngokuyintloko isixhobo esivaliweyo sokucima ubushushu, kubandakanywa nevoti okanye ebizwa ngokuba yi-scraped surface heat exchanger (iyunithi A), umatshini we-pin rotor okanye umatshini wokuxova (iyunithi C) kunye netyhubhu yokuphumla (iyunithi B). Inkqubo yeteknoloji iboniswe kuMfanekiso 2:

Le seti yezixhobo inezi mpawu zilandelayo:

1. Uxinzelelo oluphezulu lomsebenzi oqhubekayo wokungangeni moya

I-emulsion exutywe ngaphambili ifakwe kwi-cylinder yokucima ngepompo yoxinzelelo oluphezulu lokuvota. Uxinzelelo oluphezulu lunokoyisa ukuchasana kuyo yonke iyunithi, ukongeza ekusebenzeni koxinzelelo oluphezulu kunokwenza imveliso ibe mncinci kwaye igudileyo. Ukusebenza okuvaliweyo kunokuthintela umoya kunye nomoya ngenxa yokucima kunye nokuxinwa kwamanzi axutywe ne-emulsion, ukuqinisekisa iimfuno zempilo yemveliso, ukunciphisa ukulahlekelwa kwefriji.

2. Ukucima kunye ne-emulsification

I-emulsion icinyiwe nge-ammonia okanye i-Freon kwivoti ukupholisa i-emulsion ngokukhawuleza, ukwenzela ukuba ukuveliswa kweengqungquthela ezincinci ze-crystalline, ngokubanzi i-1-5 microns, ukwenzela ukuba i-taste ithambile. Ukongeza, i-scraper kwi-shaft ejikelezayo kwi-votator idibene ngokusondeleyo kunye nodonga lwangaphakathi lwe-cylinder, ngoko ke i-scraper esebenzayo ayikwazi ukukrazula ngokuqhubekayo i-crystallization ebambelele eludongeni lwangaphakathi, kodwa yenza ukuba i-emulsion ihlakazeke ukuhlangabezana ne Iimfuno ze-emulsification yethoni.

3. Ukuxova kunye nokunciphisa (umatshini we-pin rotor)

Nangona i-emulsion epholileyo yivoti sele iqalile ukuvelisa i-crystallization, isadinga ukukhula ngexesha lexesha. Ukuba i-emulsion ivunyelwe ukuba i-crystallize ekuphumleni, inethiwekhi ye-crystal lipids eqinile iya kwenza. Isiphumo kukuba i-emulsion epholileyo iya kwenza ubunzima obunzima kakhulu ngaphandle kweplastiki. Ngoko ke, ukuze ufumane iimveliso ze-margarine ngeplastiki ethile, isakhiwo sothungelwano kufuneka siphulwe ngeendlela zomatshini ngaphambi kokuba i-emulsion ifake isakhiwo sothungelwano ngokubanzi, ukuze kuphunyezwe umphumo wokunciphisa ukuqina. Ukuxova kunye nokunciphisa ukuqina kwenziwa ikakhulu kumatshini we-pin rotor.

Iyunithi A (umvoti) sisixhobo sokupholisa kwi-scraper. I-emulsion iqhutyelwa kwiyunithi evaliweyo A (umvoti) ngepompo yoxinzelelo oluphezulu. Izinto eziphathekayo zidlula umjelo phakathi kwe-cylinder yokupholisa kunye ne-shaft ejikelezayo, kwaye ukushisa kwezinto kwehla ngokukhawuleza ngokucinywa kwendawo yokupholisa. Imiqolo emibini ye-scrapers ihlelwe kumphezulu we-shaft. Iikristale ezenziwe kwindawo yangaphakathi yomvoti zichithwa yi-scraper ejikelezayo ejikelezayo ukuze ihlale iveza indawo entsha yokupholisa kwaye igcine ukuhanjiswa kobushushu obusebenzayo. I-emulsion inokusasazwa phantsi kwesenzo se-scraper. Xa izinto zidlula kwi-unit A (i-votator), izinga lokushisa liyancipha ukuya kuma-degrees angama-10-20, eliphantsi kunendawo yokunyibilika yeoli. Nangona ioli iqalisa ukukhazimla, ayikabumbeki ubume obuqinileyo. Ngeli xesha, i-emulsion ikwimeko yokupholisa kwaye ilulwelo olungqingqwa.

I-axis ejikelezayo yeyunithi A (umvoti) ayinamngxuma. Ngethuba lokusebenza, amanzi ashushu angama-50-60 degrees athululelwa embindini we-axis yokujikeleza ukukhusela i-crystallization edibeneyo kwaye iphiliswe kwi-axis kwaye ibangele ukuvala.

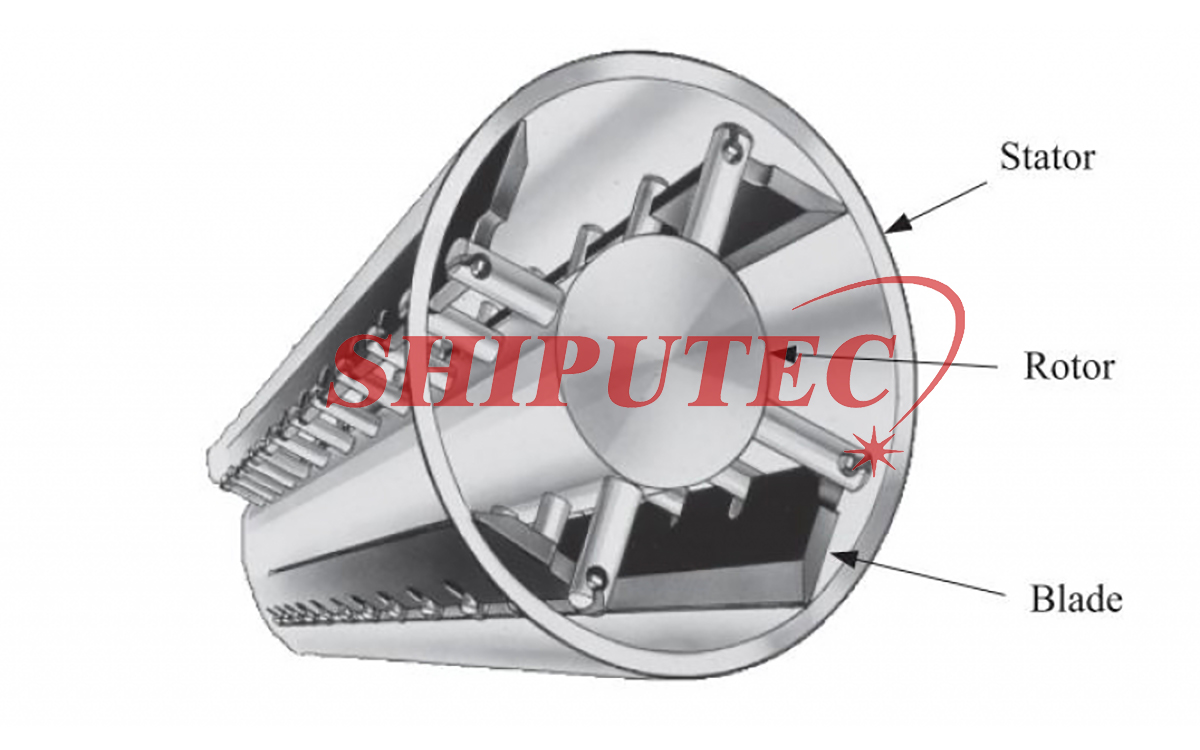

Iyunithi C (umatshini we-pin rotor) kukuxova kunye nokunciphisa isixhobo, njengoko kubonisiwe kulo mfanekiso ungentla. Imiqolo emibini yeentsimbi zetsimbi zifakwe kwi-shaft ejikelezayo, kwaye umqolo weentsimbi zetsimbi ezisisigxina zifakwe eludongeni lwangaphakathi lwe-cylinder, ezixutywe kunye neentsimbi zetsimbi kwi-shaft kwaye zingathintani. Xa i-shaft ijikeleza ngesantya esiphezulu, iibholiti zetsimbi kwi-shaft zidlula i-gap ye-bolts yensimbi esisigxina, kwaye izinto eziphathekayo zixutywe ngokupheleleyo. Ngaphantsi kwesi senzo, inokukhuthaza ukukhula kweekristale, ukutshabalalisa isakhiwo se-crystal network, ukwenza iikristali ezingapheliyo, ukunciphisa ukuhambelana, kunye nokwandisa iplastiki.

Iyunithi C (umatshini we-pin rotor) idlala kuphela isiphumo esinamandla sokuxova ngobusuku obubanda kakhulu, ngoko ifuna kuphela ukugcinwa kobushushu kwaye ayifuni kupholisa. Njengoko ubushushu becrystallization bukhutshwa (malunga ne-50KCAL/KG), kunye nobushushu obuveliswa kukuxova ukuxova, ubushushu bokukhutshwa kweyunithi C (i-pin rotor macjhine) buphezulu kunobushushu bokutya. Ngeli xesha, icrystallization imalunga ne-70% epheleleyo, kodwa isathambile. Imveliso yokugqibela ikhutshwe ngevalve ye-extrusion, kwaye iya kuba nzima emva kwexesha elithile.

Emva kokuba i-margarine ithunyelwe kwiyunithi ye-C (umshini we-pin rotor), kufuneka iphathwe ngokushushu kwiqondo lokushisa elithile. Ngokuqhelekileyo, imveliso ifakwe kwiqondo lokushisa kwe-10 degrees ngaphantsi kwendawo yokunyibilika ngaphezu kweeyure ezingama-48. Olu nyango lubizwa ngokuba kukuvuthwa. Imveliso ephekiweyo inokuthunyelwa ngokuthe ngqo kwindawo yokulungisa ukutya ukuze isetyenziswe.