AbaTshintshiseli boBushushu boMphezulu okhutshiweyo-SP Series

Iimpawu ezizodwa ze-SP series SSHEs

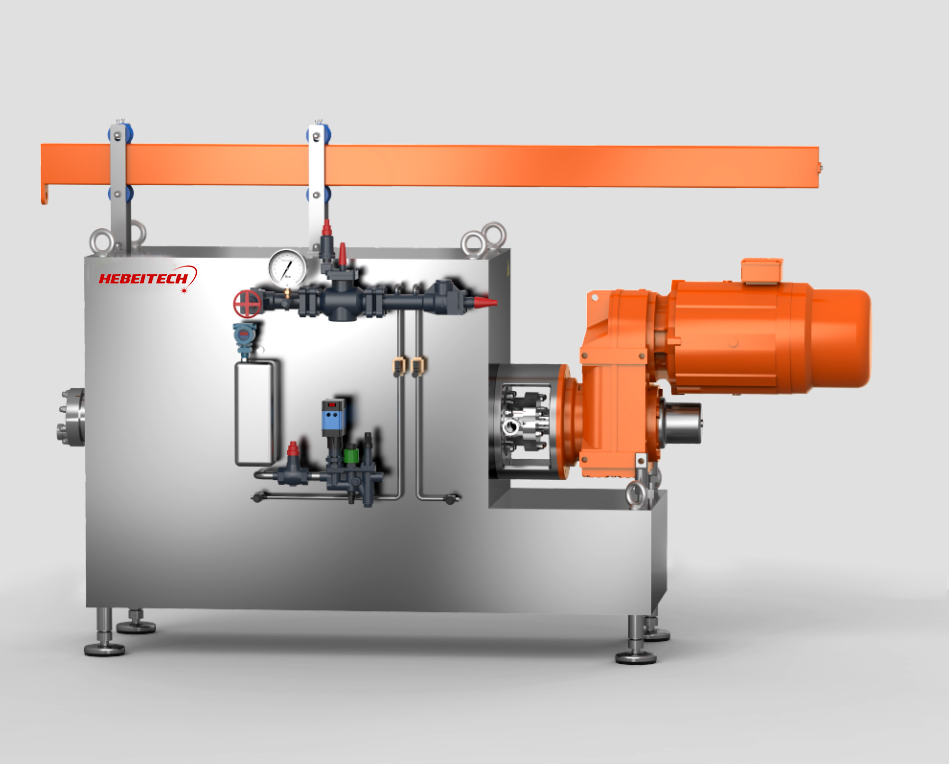

1.SPX-Plus Series Margarine Machine(Abatshintshi bobushushu be-scraper)

Uxinzelelo oluphezulu, amandla anamandla, amandla amakhulu okuvelisa

Uyilo oluqhelekileyo lwe-120bar yoxinzelelo, amandla aphezulu emoto ngama-55kW, umthamo wokwenza imajarini ukuya kuthi ga kwi-8000KG/h.

2.SPX Series Scraped Surface Heat Exchanger

Umgangatho ophakamileyo wococeko, ulungelelwaniso olutyebileyo, lunokwenziwa ngokwezifiso

Ireferensi kwiimfuno zemigangatho ye-3A, iintlobo ngeentlobo zeBlade/Tube/Shaft/Heat zingakhethwa, kwaye iimodeli ezinobukhulu obahlukeneyo zinokukhethwa ukuxhasa iimfuno zomntu.

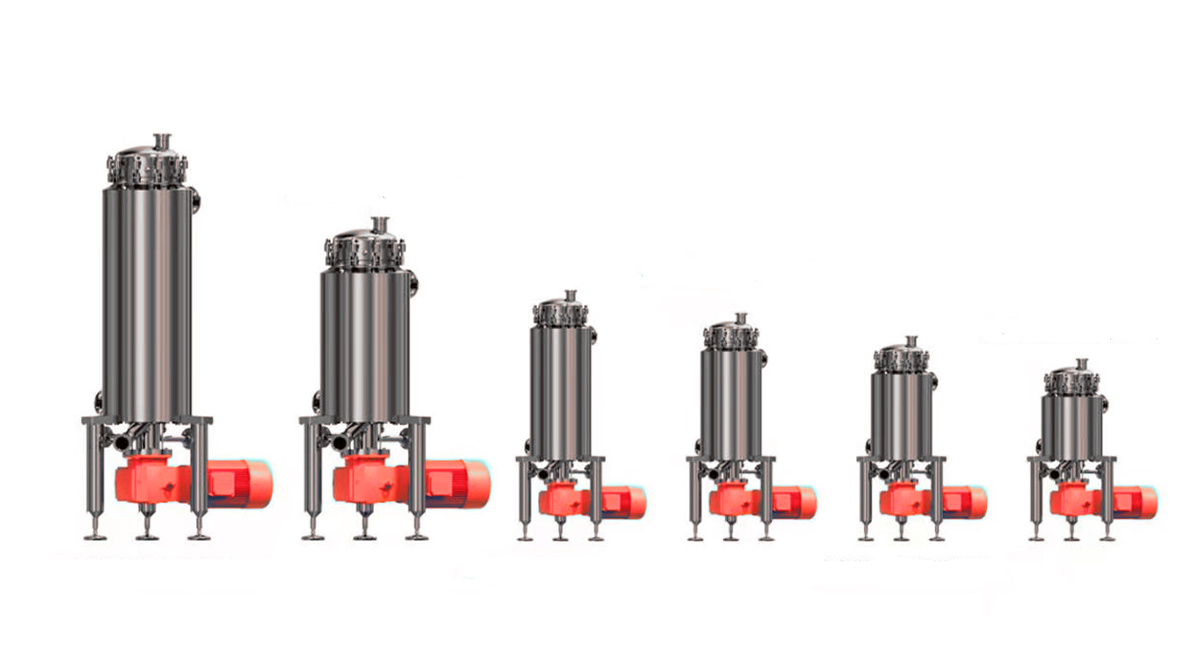

3.SPA Series Shortning Machine Production Machine (Ii-SSHEs)

Isantya esiphezulu seshafti, Umsantsa wetshaneli oMxinwa, Isikhuseli sentsimbi ende

Isantya sokujikeleza kweshaft ukuya kuthi ga kwi-660r/min, isikhewu setshaneli sincipha ukuya kwi-7mm, iscraper sesinyithi sinde ukuya kuma-763mm.

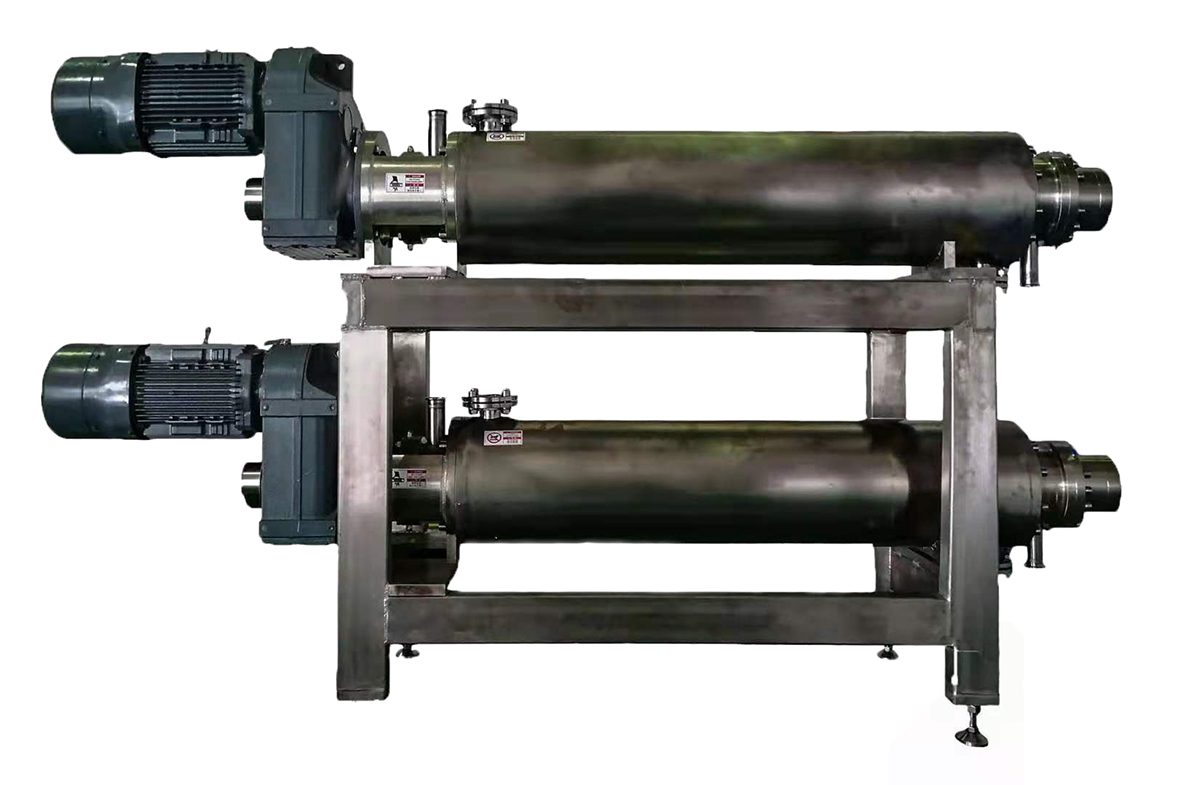

I-4.SPT Series Double Surface Scraper Ukushisa Ukutshintshana

Isantya se-shaft esisezantsi, iGap yetshaneli eBanzi, indawo enkulu yokutshintsha ubushushu

Isantya sokujikeleza kweshaft sisezantsi ukuya kwi-100r/min, isithuba setshaneli sibanzi ukuya kwi-50mm, ukuhanjiswa kobushushu obuphindwe kabini, indawo yokuhambisa ubushushu ukuya kuthi ga kwi-7 square metres.

IMargarine kunye noNxibelelwano lweMveliso yoMfutshane

I-margarine kunye nokunciphisa zidume kakhulu kwishishini lokubhaka, izinto ezikrwada zibandakanya ioyile yesundu, ioyile yemifuno, amanqatha ezilwanyana, ioyile ene-hydrogenated kunye namafutha, ioyile yaselwandle, ioli yepalm kernel, amafutha enyama, inyama yenkomo, i-palm stearin, ioyile yekhokhonathi, njl. Eyona nkqubo yokuvelisa imajarini yiMeasuring——Ingredients Configuration——Filtration——Emulsification——Margarine. ifriji——I-Pin Rotor Kneading—— (Ukuphumla)——Ukuzalisa nokuPakisha. Izixhobo ezenza isityalo sokuvelisa iMargarine Shortening ziquka iiVotators, iScraped Surface Heat Exchanger, Kneader, Pin Rotor, ityhubhu yokuphumla yemajarini, ukucutha umatshini wokuzalisa kunye nokupakisha, i-homogenizer, itanki yokufaka emulsifying, itanki yokubethela, impompo yoxinzelelo oluphezulu, i-sterilizer, icompressor yefriji. , iyunithi yefriji, inqaba yokupholisa, njl.

Apho, iiyunithi ze-SPA + SPB + SPC okanye iiyunithi ze-SPX-Plus + SPB + SPCH zenza i-margarine / i-shortening crystallization line, enokuvelisa i-margarine yetafile, ukunciphisa, i-puff pastry margarine kunye nezinye iimveliso zebhotela. Ubume be-SPA SeriesSSHEUmatshini wokwenza omfutshane ukhethekile. Emva kweminyaka emininzi yokuphucula, inozinzo oluphezulu lwezixhobo, ukucoleka kunye nokugqiba kweemveliso ezimfutshane zikhokelela eTshayina.

Ngokubanzi, SP series imajarini/shortening(ghee) inkqubo yokuvelisa:

1. I-Oil kunye ne-Fat blends kunye nesigaba samanzi silinganiswe kwangaphambili kwii-emulsion ezimbini zokubamba kunye nokuxuba izitya. Ukudibanisa kwi o ukubamba / ukuxuba izitya kwenziwa ngamaseli omthwalo alawulwa yinkqubo yokulawula ye-PLC.

2. Ukucutshungulwa kokudibanisa kulawulwa yikhompyuter enengqondo enesikrini sokuchukumisa. Itanki nganye yokuxuba / imveliso ixhotyiswe nge-mixer ephezulu yokucheba ukuze i-emulsify i-oyile kunye nezigaba ezinamanzi.

3. Umxubi uxhotyiswe ngesantya esiguquguqukayo sokunciphisa isantya sokuphazamiseka okuthambileyo emva kokuba i-emulsification yenziwe. Amatanki amabini aya kusetyenziswa njengetanki yemveliso kunye netanki yokufaka i-emulsification ngenye indlela.

4. Itanki yokuvelisa iya kusebenza kwakhona njengayo nayiphi na imveliso ephinda isetyenziswe ukusuka kumgca wemveliso. Itanki yokuvelisa iya kuba yitanki yamanzi / ikhemikhali yokucoca umgca kunye nococeko.

5. I-emulsion evela kwitanki yokuvelisa iya kudlula i-twin filter / i-strainer ukuqinisekisa ukuba akukho nto iqinileyo iya kudlula kwimveliso yokugqibela (imfuneko ye-GMP).

6. Isihluzi / isihluzi sisebenza ngenye indlela yokucoca isihluzo. I-emulsion ehluziweyo idlulela kwi-pasteurizer (imfuno ye-GMP) equkethe amacandelo amathathu e-heater plate ezimbini kunye nombhobho omnye wokugcina.

7. I-heater plate yokuqala iya kutshisa i-emulsion yeoli ukuya kwi-pasteurization yeqondo lokushisa ngaphambi kokudlula kumbhobho wokugcina ukubonelela ixesha elifunekayo lokubamba.

8. Nabuphi na ubushushu be-emulsion obungaphantsi kobushushu obufunekayo buya kuphinda busetyenziswe kwakhona kwitanki yemveliso.

9 I-emulsion yeoli efakwe kwi-pasteurized iya kungena kwisitshintshi sobushushu sepleyiti yokupholisa ukuya kutsho malunga ne-5 ~ 7-degree C ngaphezu kwendawo yokunyibilikisa i-oyile ukunciphisa amandla okubanda.

10. I-heater yeplate ifudunyezwa yinkqubo yamanzi ashushu kunye nokulawula ukushisa. Ukupholisa ipleyiti kwenziwa ngokupholisa amanzi enqaba ngevalve yokulawula ubushushu obuzenzekelayo kunye neelophu zePID.

11. Ukupompa kwe-emulsion / ukudluliselwa, ukuza kuthi ga ngoku, kwenziwa ngumpompo omnye ophezulu. I-emulsion idliswa kwiyunithi yeVotator kunye ne-pin rotor kwii-odolo ezahlukeneyo, emva koko unciphise ubushushu ukuya kwiqondo lokushisa elifunekayo lokuphuma ukuvelisa imajarini / imveliso yokunciphisa efunekayo.

12. I-oyile ye-semi-solid ephuma kumatshini wokuvota iya kupakisha okanye igcwalise nge-margarine yokunciphisa i-majarini kunye nomatshini wokupakisha.

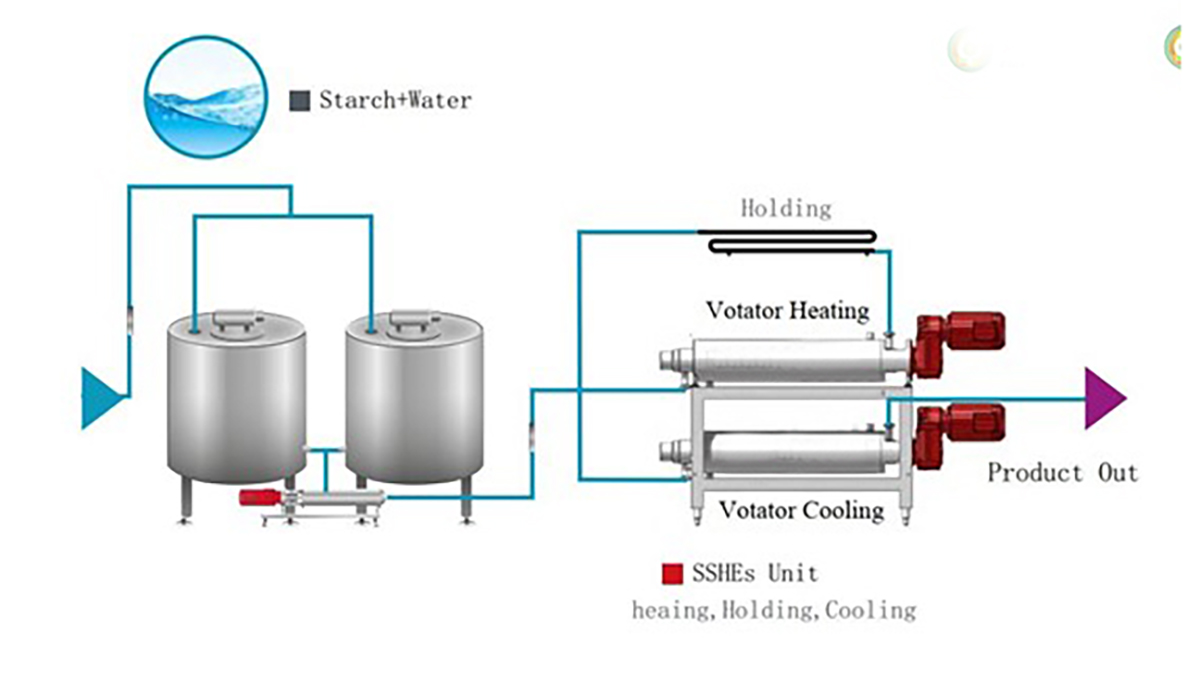

SP Series Starch / Sosi Votator Machine

Ukutya okuninzi okulungiselelwe okanye ezinye iimveliso aziphumeleli ukuhanjiswa kobushushu ngokufanelekileyo ngenxa yokuhambelana kwazo. Umzekelo, isitashi, i-scaue, i-bulky, incangathi, imveliso encangathi okanye i-crystalline equlethwe kwimveliso yokutya inokukhawuleza ivale okanye ingcolise iindawo ezithile zomtshintshi wobushushu. I-advantage scrap surface heat exchanger ibandakanya uyilo olukhethekileyo olwenza ukuba lube yimodeli yokutshintshiselana kobushushu ukufudumeza okanye ukupholisa ezi mveliso ezonakalisa ukuhanjiswa kobushushu. Njengoko imveliso impontshwa kwi-votator heat exchanger i-barrel, i-rotor kunye neyunithi ye-scraper iqinisekisa ukuhanjiswa kweqondo lokushisa elilinganayo, ukukrazula izinto ezivela kwindawo yokutshintshiselana kobushushu ngelixa ngokuqhubekayo kunye nokuxuba ngobunono imveliso.

Inkqubo yokupheka isitashi ye-SP series iqukethe icandelo lokufudumala, icandelo lokugcinwa kobushushu kunye necandelo lokupholisa. Ngokuxhomekeke kwimveliso, qwalasela enye okanye ezininzi zokutshintsha ubushushu. Emva kokuba i-starch slurry idibene kwi-batching tank, ifakwe kwisixokelelwano sokupheka ngempompo yokutya. I-SP ye-series ye-votator heat exchanger isebenzisa i-steam njengendlela yokufudumala ukutshisa i-starch slurry ukusuka kwi-25 ° C ukuya kwi-85 ° C, apho, i-starch slurry igcinwe kwicandelo lokubamba imizuzu emi-2. Izinto eziphathekayo zipholile ukusuka kwi-85 ° C ukuya kwi-65 ° CIi-SSHEsnjengesixhobo sokupholisa kunye nokusebenzisa i-ethylene glycol njengendawo yokupholisa. Izinto ezipholileyo ziya kwicandelo elilandelayo. Inkqubo yonke inokucocwa yi-CIP okanye i-SIP ukuqinisekisa isalathisi sococeko lwenkqubo yonke.

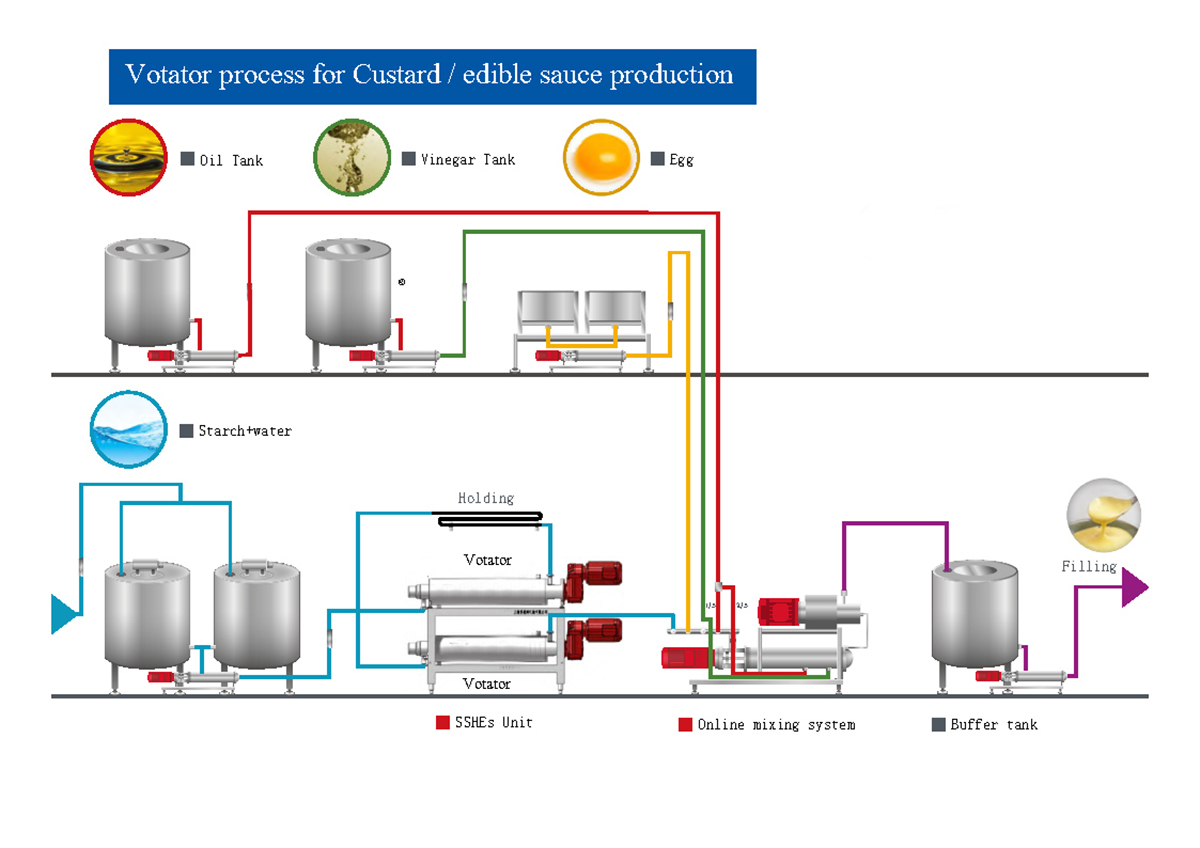

SP Series Custard / Mayonnaise Production Line

I-Custard / i-mayonnaise / umgca wemveliso yesosi etyiwayo yinkqubo yobungcali ye-mayonnaise kunye nezinye izithako ze-oyile / isigaba samanzi emulsified, ngokwenkqubo yokuvelisa i-mayonnaise kunye nokunye okunjalo, ukuvuselela. izixhobo zethu zifaneleke ngakumbi ukuxuba iimveliso ezine-viscosity efana ne-mayonnaise. I-Emulsification ingundoqo yokuveliswa kwe-mayonnaise kunye ne-Votator seriesIi-SSHEs, samkela indlela yokuvelisa esekelwe kumgaqo we-intanethi yesigaba sesithathu se-emulsification encinci, i-oyile / isigaba samanzi sahlulwe kwiiyunithi ezincinci, emva koko zadibana kwindawo yokusebenza ye-emulsifying, igqityiwe ukuxutywa phakathi kwe-emulsifier kunye ne-oyile / amanzi emulsion. . Olu luyilo luvumela umyili ukuba achaze ulwahlulo lwendawo esebenzayo kuyo yonke inkqubo yokutshintshiselana kobushushu, kwaye ngcono ukulungelelanisa kunye nokwandisa yonke inkqubo yokuvelisa. Njengakwiindawo ezisebenzayo ze-emulsion, uchungechunge lweVotator luqinisa amandla e-emulsifying, lwenza isigaba se-oyile ukuba sifakwe kwi-o-microscopic liquid drops kunye ne-complexing kunye nesigaba se-aqueous kunye ne-emulsifier okokuqala ukuze ufumane inkqubo ye-emulsion ezinzileyo ye-oyile emanzini, ngaloo ndlela. ukusombulula iingxaki ezinje ngokusasazwa kobungakanani bethontsi ye-oyile ebanzi kakhulu, uzinzo olulambathayo lohlobo lwemveliso, kunye nokuba sesichengeni kumngcipheko wokuchitheka kwe-oyile njl.njl., okubangelwa lula indlela ye-macro emulsification kunye nokuxuba iindlela zokuvuselela eziphazamisana.

Ukongeza, uthotho lwe-SP lukhuhla ubushushu bomphezulu lukwasetyenziswa kwezinye i-Heating, Cooling, Crystallization, Pasteurization, Sterilization, Gelatinize kunye ne-Evaporation eqhubekayo inkqubo.

Isixhobo esongezelelweyo

A) Amanqaku okuqala:

UTshintshiselwano loBubushushu boMphezulu oLuliweyo, uPhononongo oluBalulekileyo kwiNzululwazi yokutya kunye neSondlo, uMqulu 46, umba wesi-3

UChetan S. Rao kunye noRichard W. Hartel

Khuphela ucaphulohttps://www.tandfonline.com/doi/abs/10.1080/10408390500315561

B) Amanqaku okuqala:

IiMargarines, i-ULLMANN'S Encyclopedia ye-Industrial Chemistry, iThala leencwadi le-Intanethi yeWiley.

Ian P. Freeman, uSergey M. Melnikov

Khuphela ucaphulo:https://onlinelibrary.wiley.com/doi/abs/10.1002/14356007.a16_145.pub2

C) Uluhlu lwe-SPX Iimveliso ezifanayo ezikhuphisanayo:

I-SPX Votator® II IziTshintshiselwano zoBubushushu boMphezulu okhutshiweyo

Ndwendwela ikhonkco:https://www.spxflow.com/products/brand?types=heat-exchanger&brand=waukesha-cherry-burrell

D) Uchungechunge lwe-SPA kunye ne-SPX Series Iimveliso ezifanayo ezikhuphisanayo:

IziTshintshiselwano zoBubushushu obukhutshiweyo kumphezulu

Ndwendwela ikhonkco:https://www.alfalaval.com/products/heat-transfer/scraped-surface-heat-exchangers/scraped-surface-heat-exchangers/

E) SPT Series Iimveliso ezifanayo zokhuphiswano:

Terlotherm® IziTshintshiso zoBubushushu boMphezulu okhutshiweyo

Ndwendwela ikhonkco:https://www.proxes.com/en/products/machine-families/heat-exchangers#data351

F) I-SPX-Plus Series Iimveliso ezifanayo ezikhuphisanayo:

I-Perfector ® i-Scraped Surface Joat Exchangers

Ndwendwela ikhonkco:https://gerstenbergs.com/polaron-scraped-surface-heat-exchanger

G) I-SPX-Plus Series Iimveliso ezifanayo ezikhuphisanayo:

Ronothor® IziTshintshiso zoBubushushu boMphezulu okhutshiweyo

Ndwendwela ikhonkco:https://ro-no.com/en/products/ronothor/

H) I-SPX-Plus Series Iimveliso ezifanayo ezikhuphisanayo:

I-Chemetator® IziTshintshiso zoBubushushu boMphezulu okhutshiweyo

Ndwendwela ikhonkco:https://www.tmcigroup.com/wp-content/uploads/2017/08/Chemetator-EN.pdf