I-Pin Rotor Machine Benefits-SPCH

Kulula Ukugcina

Uyilo olupheleleyo lwe-SPCH pin rotor luququzelela ukutshintshwa lula kweendawo zokunxiba ngexesha lokulungiswa nokugcinwa. Amacandelo e-sliding ayenziwe ngezinto eziqinisekisa ukuhlala ixesha elide.

Izinto eziphathekayo

Iinxalenye zoqhagamshelwano zemveliso zenziwe ngetsimbi ekumgangatho ophezulu. Iimpawu zemveliso zilungelelanise izitywina ze-mechanical kunye nokutya-grade-O-rings. Umphezulu wokutywina wenziwa nge-silicon carbide ecocekileyo, kwaye iindawo ezihambayo zenziwe nge-chromium carbide.

Ukuba bhetyebhetye

Umatshini we-SPCH we-pin rotor isisombululo esihle kakhulu sokuvelisa i-crystallization efanelekileyo kunye nokuhambelana koluhlu olubanzi lwe-margarine kunye neemveliso ezimfutshane. Umatshini wethu we-SPCH pin rotor unikezela ukuguquguquka kwinkqubo yokuvelisa ngendlela ebaluleke kakhulu. Uhlengahlengiso lunokwenziwa ukutshintsha inqanaba lokuqina kunye nobude bokuxova. Oku kukuvumela ukuba utshintshe uhlobo lweoli, kuxhomekeke kubukho kunye nemfuno kwimarike. Ngolu bhetyebhetye, unokuthatha inzuzo yokuguquguquka kwexabiso leoli ngaphandle kokubeka esichengeni umgangatho wemveliso.

Umgaqo wokuSebenza

I-SPCH pin rotor ithatha i-cylindrical pin evuselela isakhiwo sokuqinisekisa ukuba izinto eziphathekayo zinexesha elaneleyo lokuvuselela ukuphulwa kwesakhiwo sothungelwano se-crystal fat eyomeleleyo kunye nokucoca iinkozo zekristale. Injini yimotor elawula isantya esiguqukayo. Isantya sokuxuba sinokulungelelaniswa ngokubhekiselele kumxholo ohlukeneyo weoli eqinile, enokuthi ihlangabezane neemfuno zemveliso yeendlela ezahlukeneyo zokuqulunqa abavelisi be-margarine ngokwemiqathango yeemarike okanye amaqela abathengi.

Xa umkhiqizo ogqityiweyo wegrisi oqukethe i-crystal nuclei ingena kwi-kneader, i-crystal iya kukhula emva kwexesha elithile. Phambi kokwenza ulwakhiwo womnatha jikelele, ukwenza ukuxhokonxa oomatshini kunye nokuxova ukwaphula isakhiwo womnatha eyakhiwe ekuqaleni, wenze ukuba recrystallize, ukunciphisa ukungaguquguquki nokwandisa iplastiki.

I-Pin Rotor Machine-SPCH

| Iiparamitha zobugcisa | Ubuchwephesha obuKhethekileyo. | Iyunithi | 30L | 50L | 80L |

| Umthamo olinganisiweyo | Umthamo wegama | L | 30 | 50 | 80 |

| Amandla enjini aphambili | Amandla Angundoqo | kw | 7.5 | 7.5 | 9.2 okanye 11 |

| Idayamitha yokusonta | Dia. Ye-Main Shaft | mm | 72 | 72 | 72 |

| Ukucoca ibha yokucoca | I-Pin Gap Space | mm | 6 | 6 | 6 |

| Ibha yokuxuba i-clean kunye nodonga lwangaphakathi lombhobho | I-Pin-Inner Wall Space | m2 | 5 | 5 | 5 |

| Ububanzi/ubude bomzimba wesilinda | I-Internal Dia./Ubude beThubhu yokuPholisa | mm | 253/660 | 253/1120 | 260/1780 |

| Inani lemiqolo ye-sticker | Imiqolo yePin | pc | 3 | 3 | 3 |

| Isantya sentonga yokusonta | Isantya se-Norminal Pin Rotor | rpm | 50-340 | 50-340 | 50-340 |

| Uxinzelelo oluphezulu lokusebenza (icala lemveliso) | Max.Working Pressure (icala lezinto) | ibha | 60 | 60 | 60 |

| Olona xinzelelo luphezulu lokusebenza (icala lamanzi eligcina ubushushu) | Max.Working Pressure (icala lamanzi ashushu) | ibha | 5 | 5 | 5 |

| Imilinganiselo yombhobho wemveliso | Ubungakanani bombhobho wokuqhubekisa | DN50 | DN50 | DN50 | |

| Imilinganiselo yojongano lwemibhobho yamanzi agqunyiweyo | Ubungakanani boMbhobho woBonelelo lwaManzi | DN25 | DN25 | DN25 | |

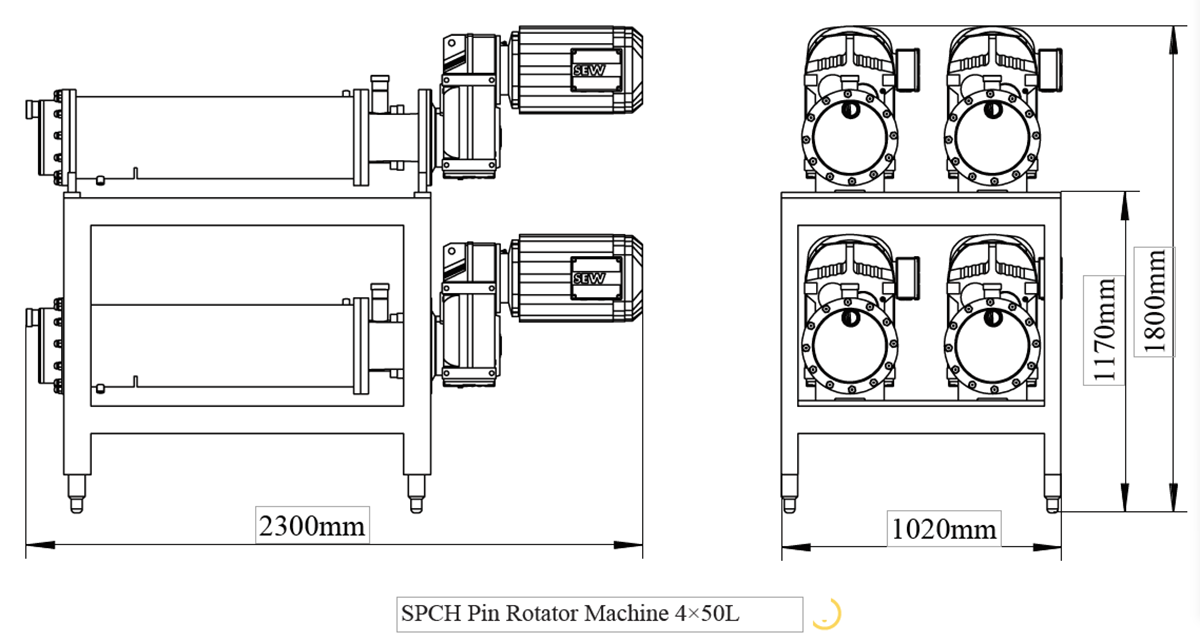

| Ubungakanani bomatshini | IDimension iyonke | mm | 1840*580*1325 | 2300*580*1325 | 2960*580*1325 |

| Ubunzima | Ubunzima bokuqala | kg | 450 | 600 | 750 |