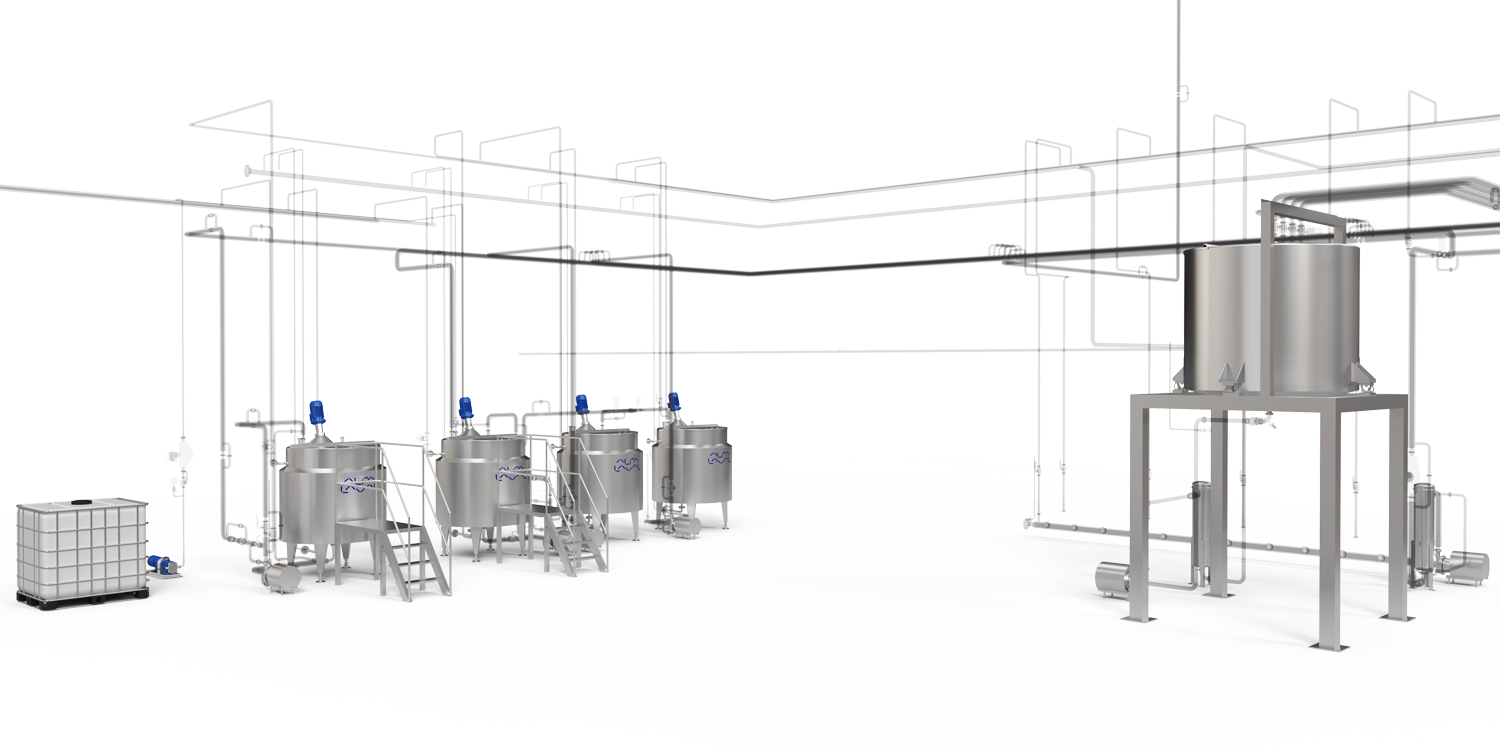

Inkqubo yokuvelisa imajarini inamacandelo amahlanu: isigaba seoli kunye nokulungiswa kwe-emulsifier, isigaba samanzi, ukulungiswa kwe-emulsion, i-pasteurization, i-crystallization kunye nokupakishwa.Nayiphi na imveliso egqithisileyo ibuyiselwa ngeyunithi eqhubekayo yokuphinda isebenze kwitanki ye-emulsion.

Isigaba seoli kunye nokulungiswa kwe-emulsifier kwimveliso yemargarine

Ipompo idlulisela ioyile, amafutha okanye ioyile edityanisiweyo ukusuka kwiitanki zokugcina ngesihluzo kwisistim sokulinganisa.Ukufumana ubunzima beoyile obuchanekileyo, le tanki ifakwe ngaphezulu kweeseli zomthwalo.Ioli edibeneyo ixutywe ngokwe-recipe.

Ukulungiswa kwe-emulsifier kufezekiswa ngokuxuba ioli kunye ne-emulsifier.Xa ioli ifikelela kumaqondo obushushu amalunga nama-70°C, izinto zokuthambisa ezifana ne-lecithin, i-monoglycerides kunye ne-diglycerides, ngokuqhelekileyo zingumgubo, zongezwa ngesandla kwitanki ye-emulsifier.Ezinye izithako ezinyibilikayo kwioyile ezinje ngombala kunye nencasa zingongezwa.

Isigaba samanzi kwimveliso yemajarini

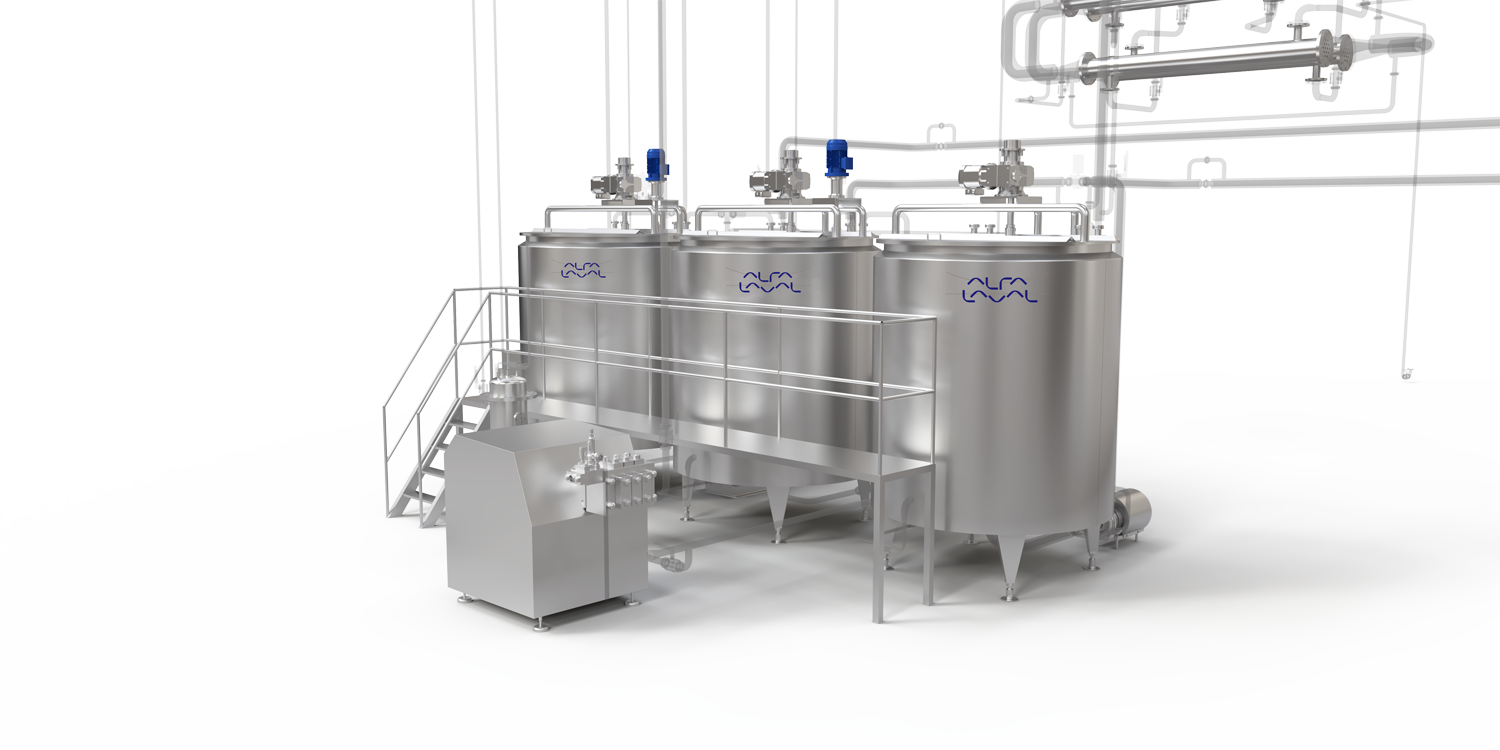

Iitanki ezigqunyiweyo zibonelelwa ngemveliso yesigaba samanzi.Imitha yokuhamba kwamanzi ithatha amanzi kwitanki apho ifudunyezwa kumaqondo obushushu angaphezu kwama-45ºC.Izithako ezomileyo ezifana netyuwa, i-citric acid, i-hydrocolloids okanye umgubo wobisi ocoliweyo unokufakwa kwitanki kusetyenziswa izixhobo ezikhethekileyo ezifana nomxube wefuneli yomgubo.

Ukulungiswa kwe-emulsion kwimveliso ye-margarine

I-emulsion ilungiselelwe nge-dosing ioli kunye namafutha kunye nomxube we-emulsifier kunye nesigaba samanzi ngokulandelelana okuxeliweyo.Ukuxuba isigaba seoli kunye nesigaba samanzi senzeke kwitanki ye-emulsion.Apha, ezinye izithako, ezifana nencasa, ivumba kunye nombala, zingongezwa ngesandla.Ipompo idlulisela i-emulsion ephumela kwitanki yokutya.

Izixhobo ezikhethekileyo, ezifana nomxube ophezulu we-shear, zingasetyenziselwa kweli nqanaba lenkqubo ukwenza i-emulsion ihle kakhulu, incinci kwaye iqine, kwaye iqinisekise uqhagamshelwano oluhle phakathi kwesigaba seoli kunye nesigaba samanzi.I-emulsion efanelekileyo ebangelwayo iya kudala i-margarine ephezulu ebonisa iplastiki enhle, ukuhambelana kunye nesakhiwo.

Impompo ke igqithise i-emulsion kwindawo ye-pasteurization.

I-Crystallization kwimveliso ye-margarine

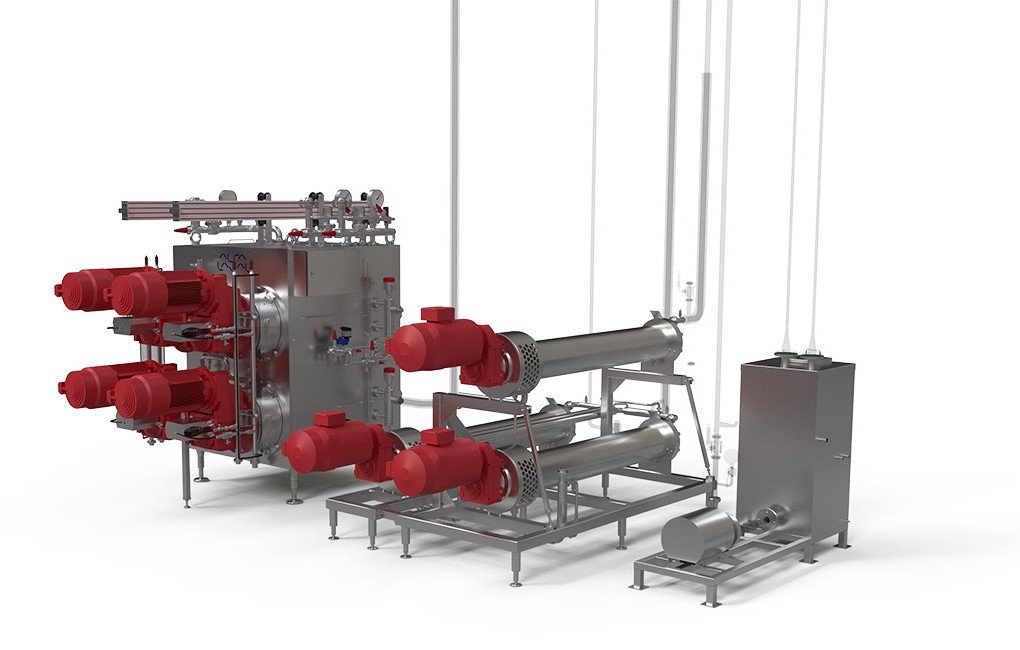

Ipompo yoxinzelelo oluphezulu idlulisela i-emulsion kwi-high-pressure scraped surface heat exchanger (SSHE), elungiselelwe ngokwezinga lokuhamba kunye neresiphi.Kusenokubakho iityhubhu zokupholisa ezahlukeneyo zobukhulu obahlukeneyo kunye neendawo zokupholisa ezahlukeneyo.I-cylinder nganye inenkqubo yokupholisa ezimeleyo apho ifriji (ngokuqhelekileyo i-ammonia R717 okanye i-Freon) ifakwe ngokuthe ngqo.Imibhobho yemveliso idibanisa i-cylinder nganye komnye.Izinzwa zobushushu kwindawo nganye ziqinisekisa ukupholisa okufanelekileyo.Iqondo eliphezulu loxinzelelo liyi-120 bar.

Ngokuxhomekeke kwiresiphi kunye nesicelo, i-emulsion inokufuna ukudlula enye okanye ngaphezulu kweeyunithi zabasebenzi bepini ngaphambi kokupakisha.Iiyunithi zabasebenzi bePin ziqinisekisa iplastiki efanelekileyo, ukuhambelana kunye nokwakheka kwemveliso.Ukuba kuyimfuneko, i-Alfa Laval inokubonelela ityhubhu yokuphumla;nangona kunjalo, uninzi lwababoneleli ngomatshini wokupakisha babonelela omnye.

Iyunithi eqhubekayo yokuphinda isebenze

Iyunithi eqhubekayo yokuphinda isebenze yenzelwe ukunyibilika kwakhona yonke imveliso engaphezulu egqithise umatshini wokupakisha ukuze uphinde ulungiswe.Kwangaxeshanye, igcina umatshini wokupakisha ungenayo nayiphi na i-backpressure engafunekiyo.Esi sixokelelwano sipheleleyo siquka ipleyiti yokutshintshiselana kobushushu, impompo yamanzi ephinda ijikeleze, kunye nesifudumezi-manzi.

Ixesha lokuposa: Jun-21-2022